With these type of machines, which rely on static to develop a charge, you end up with very high voltages and very low currents - and static discharge of electricity. These are great table-top toys, and props for bad Science Fiction movies, but not the stuff electrical power is made of.

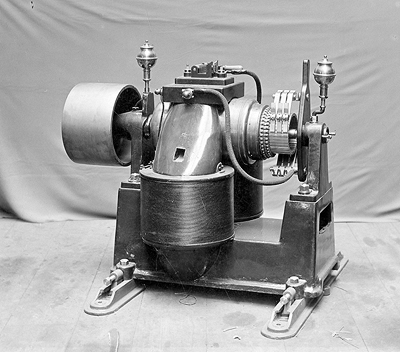

A Wimshurst generator

A Van de Graff Generator

To make significant power you need voltage, but you also need a lot of current. In 1832, Michael Faraday discovered the relationship between electric and magnetic fields, and opened the field of electromagnetism. He was a pretty impressive scientist, and his Wiki link is here. He discovered a lot more than electromagnetism. For our purposes though, his theory of electromagnetism allowed enough understanding of electricity to finally build a practical generator to connect to a steam engine.

The earliest practical generators were direct-current machines called dynamos. Direct current is the type of current that a battery produces. Current flows only in one direction, from the negative terminal to the positive terminal. Back in the day, nobody knew what to do with Alternating Current, so the desire was to generate Direct Current,

Here is a photo of Faraday's early disc-type dynamo. The horseshoe magnet "A" puts a magnetic field on spinning copper disk "D". The magnetic field and motion cause electrons to move to the center of the disk. Post "B" takes the electrons off the center of the disk, while foil strip "m" and post B' provide a return path for the electrons to the edge of the disk, completing the DC circuit, and allowing current to flow!

This machine was able to develop electricity at useful voltages, and generated a continuous current, unlike the earlier static generators.

The next important development for Direct Current generators was the invention of the commutator. The purpose of a commutator is to mechanically convert the alternating current (AC) that a wound-coil machine produces into direct current, or DC current. This next generator was built using Faraday's principles, and was invented by Hippolyte Pixii.

This is a pretty crude machine, but it does the job. When the handle is cranked, the horseshoe magnet spins underneath the coils. It generates Alternating Current (AC), because when the north pole of the magnet passes under a coil, the current flows one direction. Then half a turn later the south pole of the magnet causes the current to flow in the opposite direction.

The genius of this device is the commutator underneath the magnet. There are two segments stacked on each other, but insulated from each other. The AC power from the coils is applied to the commutator using wires touching the metal, but it is only removed from the commutator when the voltage is at its positive and negative peak in one direction.

This machine also had limitations. It only had two coils, so the electrical power output was pretty much a series of DC pulses, with zero power output in between, so it didn't have a very good average power output.

The first practical dynamo, and the one first used for power generation, was the Gramme Dynamo. It had multiple poles (windings) to smooth the electrical power delivery, and iron plates to concentrate the magnetic fields and increase power output. Note the massive magnet, the iron wedges between windings on the rotor, the minimal air gaps between rotor and stator, and the large number of segments on the commutator.

Below is a cutaway of a small modern dynamo, or DC generator. As the rotor spins, the magnets (two gray blocks inside the case) induce voltage on the windings. One end of each winding is connected to a segment of the commutator (6), 180 degreees from each other. When voltage on on a winding is at maximum (winding directly next to the magnet), the carbon brushes (5) take voltage off that segment of the commutator. As the rotor turns, another winding peaks, and the next commutator segment rotates into contact with the brushes. This is how AC power is mechanically converted to DC power. Very clever!

Below is an industrial-type dynamo that might have been connected to a Corliss steam engine at some point in time. Mechanically, power input is via a wide drive belt on the left. The shiny globes are oilers for the bearings. Electrically, the two large coils create an electric field through which the rotor spins. Multiple windings (not seen) on the rotor have electicity induced on them. Three brushes to the right take the electricity off each winding while it is at its maximum point of generation, converting the AC into DC power. Thick wires lead from the brushes to the top of the generator, which is called the generator terminal. A smaller wire to the left of the block on top of the generator is connected to the coils below. A portion of the machine's output is needed to maintain the magnetic field. This principle is called self-excitation.

Here is an example of a dynamo with a separate excitation generator. The smaller machine provides a variable amount of electrical current needed by the coils in the larger machine. In this way, varying the output of the smaller machine adjusts the output voltage of the larger one. Obviously separate excitation is a more complex arrangement, and therefore there is more that can go wrong.

Below is a dual piston-type steam engine connected to a six-pole (winding) dynamo. The next post will be about the big war of DC vs AC. Of Westinghouse and Tesla squaring off against Thomas Edison. Fascinating history!

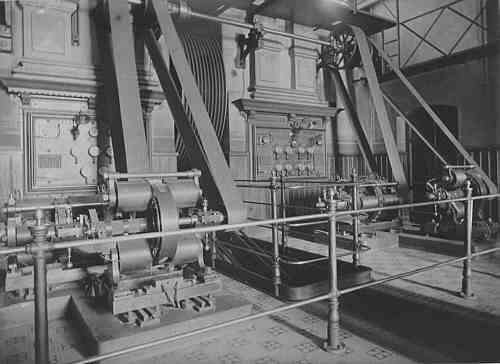

Lastly, below is a photograph of the one of the world's first electrical power plants. It may have been electrically and mechanically dangerous, but that's just cool!

No comments:

Post a Comment