"Obscurity and a competence - that is the life that is best worth living." - Mark Twain

One of the recent posts here was about thermodynamics, with a brief overview of the energy contained in steam and water at various points in the steam cycle. The goal was to see if I could manage to calculate efficiency of the steam cycle here at work and show the results to our new guys. I didn't get far with that project yet, for reasons I will explain in an upcoming post.

Today's post though, is about turbine inlet temperature - in both the gas turbine and the steam turbine, and how and why this temperature must be tightly controlled.

Turbine blades on two pole turbogenerators (and aircraft engines) are under an incredible amount of tensile stress. This makes sense, as they are attached to a rotor that is spinning 3600 RPM (that's 60 times in one second folks!!!) in a power plant, and perhaps 9500 RPM in aircraft applications. Centrifugal force is responsible for the tensile stress. Total force of the tensile stress is mass x velocity squared, divided by the radius.

To reduce the tensile stress, it is necessary to reduce weight, reduce the velocity, or the radius. All of this is done in the design stage of a turbine, so there is nothing that an operator can do about these things. The tensile stress will be whatever the engineers decided is a safe value for the materials and dimensions that have been built into the machine.

All turbine blades experience creep. Creep is the stretching out of a turbine blade due to the extreme amount of centrifugal force that it experiences while the turbine is in operation. When the turbine is taken out of service, the tensile force is gone, and the blade returns to its normal dimensions.

Gas and steam turbine blades are *also* exposed to very high temperatures, particularly the first stage at the inlet to the turbine. It is here that the combustor exhaust or steam inlet temperature is highest, and so in this environment the blades are far more likely to become ductile. That said, the longer and heavier blades in the back end of the turbine also experience creep, but this is not generally related to temperature - it is mostly due to material fatigue.

This change in ductility with temperature is expected and accounted for by the designers, and the turbine is designed with adequate clearance to allow for this tenperature-related creep. HOWEVER, if the temperature exceeds the design limits, the turbine blades can lose some of their elasticity and be stretched permanently. That is, when the machine is shut down, they no longer return to their original dimensions. Overheating the turbine blades can lead to excessive creep and allow the blade tips of the turbine to rub against the casing. A rub can lead to catastrophic failure in short order, due to friction heating, imbalance, airflow disruption, and high frequency vibration causing root failure of the turbine blade attachment - flinging the blade off the turbine.

Excessive creep and related failures due to overheating is usually not immediate. The blade can take a large temperature spike for a brief time, or a smaller temperature increase over a longer period of time without experiencing enough creep to cause engine damage. However it's best to not do this at all - we try to maintain turbine inlet temperature as hot as possible for efficiency, while not exceeding the limit and creating the conditions needed to cause creep.

And now at long last, we are down to the subject: Controlling the inlet temperature of the turbine.

Let's discuss the gas turbine first, since the operator doesn't control that at all - the hardware does.

The TIT or Turbine Inlet Temperature, is a calculated value. There is no way to directly monitor the gas temperature entering the turbine, as these temperatures would destroy any probe in short order. Turbine exhaust temperature is monitored around the circumference of the gas turbine and averaged.

Instead it is necessary to work backwards from the exhaust thermocouples. We know the exhaust temperature, and we know how many megawatts the generator produces, and how much heat extraction the turbine has to do to get those megawatts, and how efficient the turbine is. So working backwards, with a real-time calculation, we can derive the TIT or turbine inlet firing temperature, from the temperature of the exhaust gas leaving the turbine.

Below: Exhaust thermocouples on the gas turbine.

On this particular turbine design, there are 27 exhaust thermocouples that are used to monitor combustion and to limit how much fuel is added when the engine is at maximum firing temperature.

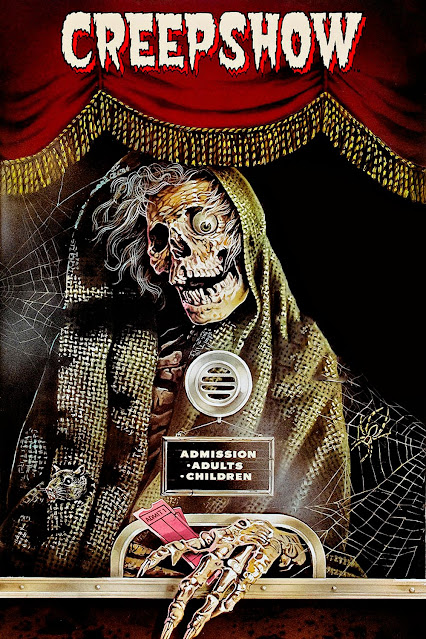

Below: A graphic image representing the conditions in the image above! The exhaust is hot, but the inlet of the turbine is much hotter.

Below: Fuel flow for the gas turbine can be limited by a number of parameters. This box shows us which parameter is most limiting at the moment. When firing temperature is controlling, the turbine is burning as much fuel as possible, and it is at full load, and being limited by turbine inlet temperature, at which point blade creep is a concern.

Again, the operator has no control over the temperature of the gas turbine inlet temperature. That's all done at the hardware and software level. As a result, unexpected creep is not an issue on the gas turbine. The blades will creep (elongate) to a known extent over their lifetime and be replaced at regular maintenance intervals.

Side note here: Gas turbine blade development has made amazing progress in the past few decades. The earliest blades were cast with the best possible materials, but still suffered from short life due to the grain structure of the metal. Since each blade contained millions of individual crystalline metallic grains, the blades tended to creep and fail at a microscopic level at each grain boundary, shortening their lifespan.

The next development was grain alignment, where metallic crystal grains were directionally aligned along the length of the blade, making it much stronger along the blade length. The final development was the "single crystal" blade, which is essentially a single metallic grain, with no interfaces at all between grain boundaries to provide a point of failure or weakness.

Below: Each of the three turbine blade grain structures.

Below: Blade life for each of the crystalline structure blades. The dashed line is the allowable creep limit.

That's the Gas Turbine, which we don't have much control over. It's all been engineered, and the hardware and software adjust the firing temperature in real-time. Let's turn to the steam turbine, where as operators, we have a lot more to worry about.

To my knowledge, only nuclear and geothermal turbines use saturated steam. Saturation conditions protect the steam turbine from overheating and blade creep, as saturated steam isn't terribly hot by metallurgical standards. Superheated steam is used everywhere else in electrical generation, and

that steam *is* hot enough to cause creep on turbine blades.

Steam boilers are designed to generate enough volume of steam and superheat it, to carry the desired amount of energy to the turbine. The superheater section of a boiler is typically over-sized. It has more heat transfer surface area than needed, so that that in the event tubes fail and are welded shut (or fuel is off-spec), the desired steam temperature can still be achieved.

A superheater section usually consists of a primary superheater, an attemporator, and a secondary superheater. This arrangement is called a two-pass superheater. I looked for a diagram of a two-pass superheater online, and didn't find anything that worked, so I was forced to draw one :) The point where "High Pressure Water" enters the steam line, is called an "Attemporator". Should have put that on the drawing.

In the above drawing, steam flows from left to right, while hot gas flows from right to left. Heat is added to the steam in the primary superheater, raising its temperature. Water is admitted between the primary and secondary superheater, to control the steam temperature on the outlet of the secondary superheater. A simple logic loop controls the temperature of the steam leaving the secondary superheater by adjusting the flow of water into the attemporator, just before the steam enters the secondary superheater.

The reason it's designed this way is so that in the event the water valve fails open, you don't put water into the steam turbine. The secondary superheater will vaporize any excess water you accidentally put in. But if the water valve fails shut, you can get very high temperature steam that could cause creep in the steam turbine blades.

Steam turbine blades are nowhere near as robust as gas turbine blades, as the temperature they operate at is much lower - typically 1000-1050 degrees F (538-565C). Steam turbine blades are not made of superalloy, and they are not intended to be replaced on a routine maintenance schedule. Rather, they are intended to last the life of the power plant. These operating temperatures are designed to maintain the highest possible efficiency while also avoiding creep.

When a power plant is operating at full power, the gas flow conditions and steam flow conditions are at the design parameters. Since this is where the plant is intended to be operated, typically steam temperature, pressure and flow are under good control. It's when the plant is operated at reduced load that you see steam temperature in particular get out of hand.

Hot gas flow is reduced, and the front end tubes of the boiler tend to capture more heat, leading to higher temperatures and lower steam production, as there is less heat available in the evaporation section. On a plant that uses a gas turbine as the heat source, things tend to be a little worse. The inlet guide vanes restrict airflow to maintain a high exhaust temperature on the engine to keep steam cycle efficiency high at reduced loads.

Often the steam attemporator control loop tuning doesn't react quickly enough to a load change. Many of these control loops don't react quickly - so it's up to the operator to intervene, and spray more water into the superheaters to prevent steam turbine damage. One of the most difficult power plants I had to operate from the standpoint of steam temperature control was start-ups on this coal-fired boiler. The very last paragraph is a remark on high steam temperature :)

No comments:

Post a Comment