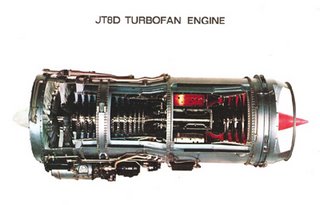

This is a cutaway of the impressive Pratt-Whitney JT8D turbofan. It's an aeroderivative engine used in peaking power plants, and the main competition to the GE LM2500.

A photo of the inlet end.

These are the engines I alluded to in a previous post that actually produce thrust (actually expanding hot gas) in a power plant environment, rather than shaft output. The engine rests on a stand, with the inlet connected to an air filter by ductwork. The exhaust is directed into a turbo-expander (not unlike a water-wheel arrangement) that converts the expanding gas into rotating energy, with the shaft perpendicular to the direction of thrust. Impressive fact: A single low-bypass aircraft engine can provide about 23 Megawatts of electricity.

Aeroderivative engines are high-maintenance. They are frequently changed out when parts fail on them.

The advantage of this arrangement over the LM2500 is that no alignment is required. The fuel lines, instrumentation and duct work are removed, and the engine can be pulled. Replacement is the reverse. The LM2500 must be carefully aligned with the generator shaft in addition to all of the above items. It lengthens the downtime when failure occurs.

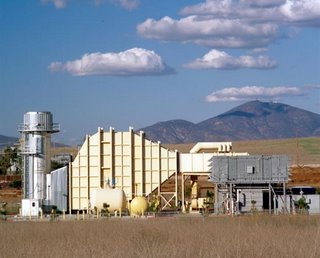

Below: JT8D installation. Looking at the exhaust into the turboexpander.

I have not operated these type plants much at all, but according to co-workers, the JT8D can handle a compressor stall better than the GE machines as well.

Here's a photo of a dual JT8D installation:

No comments:

Post a Comment