An early and very common valve arrangement was the "flathead" engine.

With a flathead engine, the intake and exhaust valves are set into the engine block. This of course makes casting the engine block quite a bit more difficult, because it has intake and exhaust runners inside the block, as well as valve guides. However the cylinder head is bare and simple, and very easy to manufacture. Take a look at the Ford flathead V-8 engine block below:

A couple of things you might notice about this arrangement that are less than optimal: The valves are in a cold zone, well away from where combustion is occurring. This makes it difficult to get a complete fuel burn, and emissions suffer as a result. Also, the inlet and exhaust gas have to take a very serpentine route to get into and out of the engine, creating significant shortcomings in breathing and cooling.

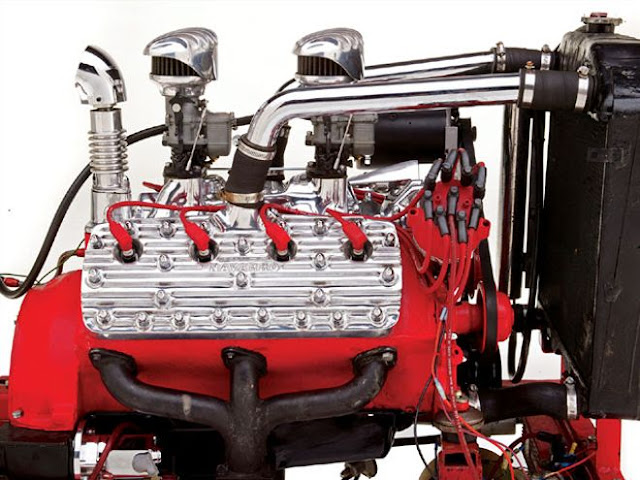

Below is an assembled flat head engine. These are highly prized by retro hot-rodders. In their day, these engines were the one to beat. Unlike a modern engine with the valves in the cylinder head, the size of the valves is not limited to what can be fit into a combustion chamber above the piston - and so at the time, these were not bad engines for backyard mechanics to hot-rod.

Note how the exhaust manifold (black pipes at bottom) actually bolts to the engine block! Flathead engines are identifiable by having very thin cylinder heads, with oodles of bolts, frequently with air-cooling fins on them, because often there was no water cooling for the cylinder heads.

Same design on a motorcycle. Again, intake and exhaust attach to the cylinder (horizontal fin section), rather than the cylinder head.

The Briggs and Stratton engine on your older lawn mower is likely a flathead design as well.

Overhead Valve Engines:

A far more practical and common engine design is the overhead valve (OHV) arrangement. With this engine design, the engine block no longer has intake and exhaust valves and their associated passages built into it. Instead the cylinder head contains all these components. This makes the engine block much simpler to manufacture, but manufacturing the cylinder heads of course becomes more difficult.

Adjusting the valves, and repairs to the valve train are a great deal simpler on an OHV engine than a Flathead engine, which is why it displaced the Flathead design. The overhead valve engine was a stalwart the of US automotive industry for 50 years. Only recently have OHV engines given way to more complex Dual Overhead Cam engines, which are more fuel-efficient and emission-friendly

Below is a really nice diagram of how the valve arrangement works on an OHV (or pushrod) engine.

With this design, the camshaft lifts a pushrod up when the valve needs to be opened. The pushrod in turn lifts a rocker arm, which pivots on the rocker shaft, reversing the motion, and pushing the valve down into the cylinder, allowing air to flow into the engine and exhaust to flow out, as necessary.

This design is simple to manufacture, and it's very easy to adjust the valve clearances, compared to most other valve-train designs. It's easy to see why this arrangement became quite common, and lasted for so long. Air-Cooled OHV engines are easy to identify because frequently have external pushrod tubes and oddly-shaped valve covers to enclose the rocker arms. Below are some air-cooled OHV engines.

Below, a radial airplane engine. Pushrods in the tubes actuate intake and exhaust rocker arms in the knobby boxes outboard of each cylinder.

Harley Davidson Knucklehead engine

Norton 850 Commando Engine. With this design, the pushrods are internal to the engine, so no pushrod tubes are visible. The rocker covers are funky-shaped, with little access doors to adjust the valve clearances (required frequently!).

Below are some common water-cooled automotive OHV engines. The numbers associated with each engine are their displacement in cubic inches. Displacement is the diameter multiplied by the stroke of a cylinder, multiplied by the number of cylinders. (bore x stroke x number of cyl = displacement)

Ford 289 with valve covers removed.

The ubiquitous Chevy 350

Dodge 360 (the rocker arms are a high-performance after-market design, called "roller rockers")

A stock small-block OHV car engine has narrow cylinder heads covered by cheap stamped steel valve covers. Low price, easy maintenance, and modest performance were the keys to the success of these engines. Below is an example of an assembled engine..

One thing you may have noticed about all of the above engines is that the intake and exhaust valve are both on the same (outboard) side of the engines. This means the intake fuel/air mixture has to cross over above the cylinder, inside the head, and then bend down 90 degrees or more to actually enter the cylinder. Not exactly a direct shot into the cylinder....

Also recall that the intake mixture only has atmospheric pressure to flow, so the intake requires larger passages and valves than the exhaust. Air flow (which improves power output) on a standard OHV engine is not nearly as good as it could be, and hot-rodders spend a lot of money, time, and effort trying to improve upon the stock designs. After-market fixes include enlarging and polishing the intake runners, installing cylinder heads with larger valves (above), and installing cams that have more valve lift and/or hold the valves open longer.

There are ways for the engine designer to engineer improved airflow on an OHV pushrod engine though. Canted valves! With canted valves, the intake valve is closer to the center of the engine than the exhaust valve, and so the flow path into the cylinder is more direct, with fewer bends and turns. This was a more expensive engine design than standard OHV engines, and was marketed toward racers and to high performance enthusiasts.

The first canted-valve engine available to the public. The Chevy 409 (the Beach boys wrote a song about it). Notice that the intake valves are a little closer inboard, nearer where the intake is? The fuel/air mixture has a straighter shot into the cylinder. These were known as "porcupine motors", because the valve stems stuck out at different angles instead of being inline with each other.

Ford 351 Cleveland cylinder head (from underneath). The larger valve openings are intakes.

Ford Boss 429. Some nearly straight runs here, with massive intake ports! The flow path is almost directly across the cylinder head.

Identifying a canted-valve engine is pretty easy. They have HUGE valve covers, because the cylinder head is quite a bit wider - to accommodate the very spread-out valve arrangement. Below is the Ford Boss 429 assembled in a car. Big valve covers...

The best arrangement possible for a pushrod engine is the cross-flow cylinder head with hemispherical combustion chambers, known as "Hemi engines".

With this arrangement, the fuel/air mixture flows directly in, is burned and flows directly out the other side. Breathing is optimized, as is power. Hemi engines are quite easy to identify, because there are holes in the valve covers that the spark plugs are set into.

Below, the Dodge 426 Hemi engine, a drag-racing favorite since the 1970's. Most professional drag racing engines are based on this engine.

Below, a modern automotive Dodge Hemi engine. Again, the spark plugs enter the valve covers.

Next up, overhead cam engines.

1 comment:

Thanks for that information, Partsguy. I was not aware that the new "Hemi" engines were not like the earlier generations. I will modify the post in the near future to correct that error!

Post a Comment